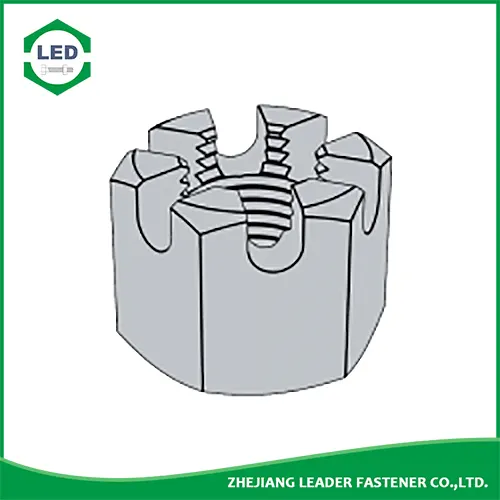

Kacang Istana DIN 935

Leader-Fastener® ialah pengeluar dan pengedar DIN 935 Castle Nut. Kami mempunyai barisan perkhidmatan yang lengkap daripada melabur dalam kilang pengeluaran, jabatan eksport dan mempunyai pasukan kawalan kualiti dan pusat untuk memenuhi keperluan anda. Kami menganggap kualiti sebagai kehidupan syarikat. Kami mengekalkan kualiti yang baik sebagai dasar pertama dan telah mewujudkan satu set kawalan kualiti dan sistem pemeriksaan mengikut piawaian antarabangsa. Kami telah menjalankan Sistem Jaminan Kualiti ISO9001 dalam setiap proses pengeluaran, pengangkutan dan penjualan. Kami berharap kami boleh menjadi rakan kongsi anda dalam perniagaan dengan mengungguli kualiti, perkhidmatan kesatria dan harga yang kompetitif dalam masa terdekat dan menjadi rakan anda juga.

Hantar Pertanyaan Muat Turun PDF

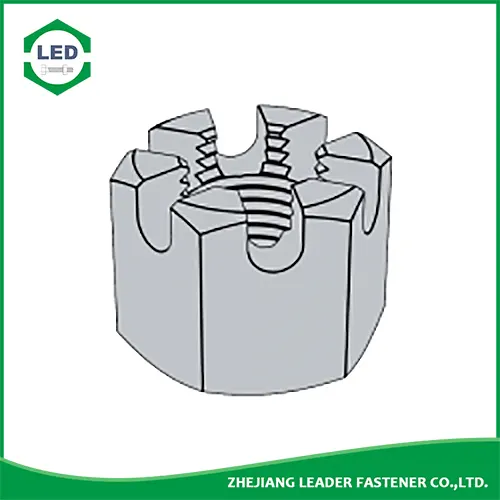

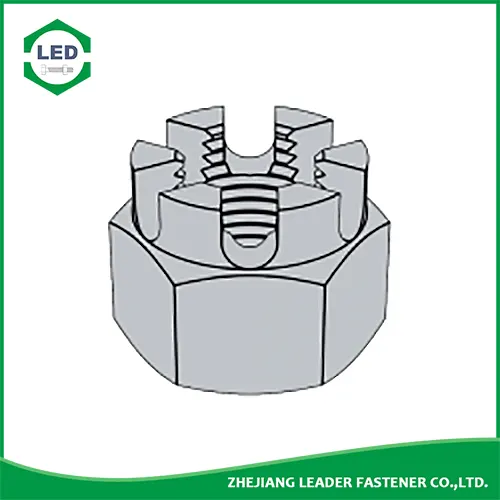

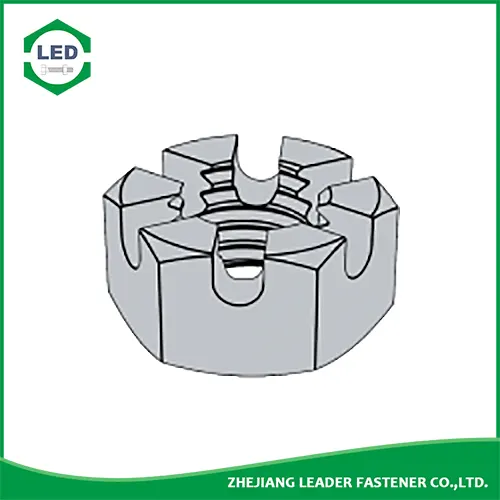

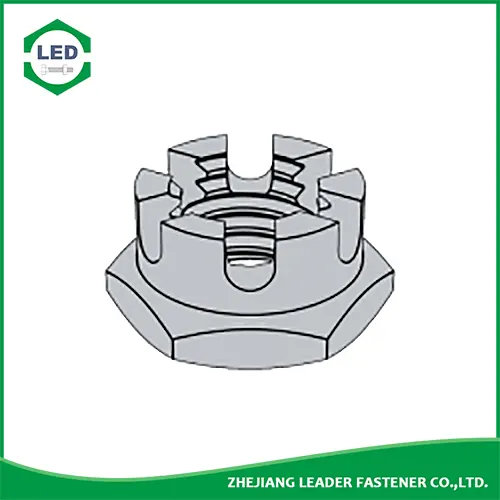

MetrikNat Istana Berslot Heksagon DIN 935ialah kacang hex di mana slot dipotong ke dalam satu sisi nat (DIN 935 sehingga 12mm diameter) atau melalui mahkota (diameter > 12mm). Slot ini direka bentuk untuk menawarkan ciri mengunci di mana pin belah/pin cotter (DIN 94), klip R atau wayar keselamatan boleh dijajarkan melalui slot dan dipandu melalui lubang yang digerudi pada batang bolt yang dipadankan.

Spesifikasi Produk Leader-Fastener®Kacang Istana DIN 935

Bahan: Keluli karbon, Keluli tahan karat, Keluli Aloi, Loyang.

Kemasan: Hitam, Bersalut Zink, Zink Kuning, HDG, Fosfat, DACROMET, Geomet, Magin, Ruspert, Teflon, dll.

Pemimpin-Pengikat® DIN 935-1 - 2013 Hexagon Slotted dan Castle Nuts - Bahagian 1: Benang Metrik Kasar dan Halus, Gred Produk A dan B

| Saiz benang D |

M4 | M5 | M6 | (M7) | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | |

| P | Pitch (Benang kasar) | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 |

| Benang halus-1 | - | - | - | - | 1 | 1.25 | 1.5 | 1.5 | 1.5 | 1.5 | 2 | 1.5 | 2 | 2 | 2 | 2 | |

| Benang halus-2 | - | - | - | - | - | 1 | 1.25 | - | - | 2 | 1.5 | 2 | - | - | - | - | |

| da | maks | 4.6 | 5.75 | 6.75 | 7.75 | 8.75 | 10.8 | 13 | 15.1 | 17.3 | 19.5 | 21.6 | 23.8 | 25.9 | 29.2 | 32.4 | 35.6 |

| min | 4 | 5 | 6 | 7 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | |

| de | maks | / | / | / | / | / | / | 16 | 18 | 22 | 25 | 28 | 32 | 34 | 38 | 42 | 46 |

| min | / | / | / | / | / | / | 15.57 | 17.57 | 21.48 | 24.3 | 27.3 | 31 | 33 | 37 | 41 | 45 | |

| dw | min | 5.9 | 6.9 | 8.9 | 9.5 | 11.6 | 14.6 | 16.6 | 19.6 | 22.5 | 24.9 | 27.7 | 31.4 | 33.2 | 38 | 42.7 | 46.6 |

| e | min | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 | 23.35 | 26.75 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 |

| m | max=saiz nominal | 5 | 6 | 7.5 | 8 | 9.5 | 12 | 15 | 16 | 19 | 21 | 22 | 26 | 27 | 30 | 33 | 35 |

| min | 4.7 | 5.7 | 7.14 | 7.64 | 9.14 | 11.57 | 14.57 | 15.57 | 18.48 | 20.16 | 21.16 | 25.16 | 26.16 | 29.16 | 32 | 34 | |

| w | maks | 3.2 | 4 | 5 | 5.5 | 6.5 | 8 | 10 | 11 | 13 | 15 | 16 | 18 | 19 | 22 | 24 | 26 |

| min | 2.9 | 3.7 | 4.7 | 5.2 | 6.14 | 7.64 | 9.64 | 10.57 | 12.57 | 14.57 | 15.57 | 17.57 | 18.48 | 21.48 | 23.48 | 25.48 | |

| m1 | min | 2.3 | 3 | 3.8 | 4.2 | 4.9 | 6.1 | 7.7 | 8.2 | 9.8 | 11.2 | 11.9 | 13.5 | 14.2 | 16.6 | 18.2 | 19.8 |

| n | maks | 1.45 | 1.65 | 2.25 | 2.25 | 2.75 | 3.05 | 3.8 | 3.8 | 4.8 | 4.8 | 4.8 | 5.8 | 5.8 | 5.8 | 7.36 | 7.36 |

| min | 1.2 | 1.4 | 2 | 2 | 2.5 | 2.8 | 3.5 | 3.5 | 4.5 | 4.5 | 4.5 | 5.5 | 5.5 | 5.5 | 7 | 7 | |

| s | max=saiz nominal | 7 | 8 | 10 | 11 | 13 | 16 | 18 | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 |

| min | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | |

| Siri â¡ | Pin Pisah seperti dalam DIN EN ISO 1234 | 1x10 | 1.2x12 | 1.6x14 | 1.6x14 | 2x16 | 2.5x20 | 3.2x22 | 3.2x25 | 4x28 | 4x32 | 4x36 | 5x36 | 5x40 | 5x45 | 6.3x50 | 6.3x56 |

| setiap 1000 unitâkg | 1.12 | 2.3 | 3.16 | 3.96 | 7.35 | - | - | - | 38.9 | 57.5 | 75.2 | - | 131 | 192 | 264 | 333 | |

| Saiz benang D |

M36 | (M39) | M42 | (M45) | M48 | (M52) | M56 | (M60) | M64 | (M68) | M72 | (M76) | M80 | (M85) | M90 | M100 | |

| P | Pitch (Benang kasar) | 4 | 4 | 4.5 | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 | 6 | - | - | - | - | - | - |

| Benang halus-1 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 6 | 6 | |

| Benang halus-2 | - | - | - | - | - | - | - | - | - | - | 4 | 4 | 4 | 4 | 4 | 4 | |

| da | maks | 38.9 | 42.1 | 45.4 | 48.6 | 51.8 | 56.2 | 61 | 64.8 | 69.1 | 73.4 | 77.8 | 82.1 | 86.4 | 91.8 | 97.2 | 108 |

| min | 36 | 39 | 42 | 45 | 48 | 52 | 56 | 60 | 64 | 68 | 72 | 76 | 80 | 85 | 90 | 100 | |

| de | maks | 50 | 55 | 58 | 62 | 65 | 70 | 75 | 80 | 85 | 90 | 95 | 100 | 105 | 110 | 120 | 130 |

| min | 49 | 53.8 | 56.8 | 60.8 | 63.8 | 68.8 | 73.8 | 78.8 | 83.6 | 88.6 | 93.6 | 98.6 | 103.6 | 108.6 | 118.6 | 128.4 | |

| dw | min | 51.1 | 55.9 | 60.6 | 64.7 | 69.4 | 74.2 | 78.7 | 83.4 | 88.2 | 92.9 | 97.7 | 102.4 | 107.2 | 111.9 | 121.1 | 135.4 |

| e | min | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 | 110.51 | 116.16 | 121.81 | 127.46 | 133.11 | 144.08 | 161.02 |

| m | max=saiz nominal | 38 | 40 | 46 | 48 | 50 | 54 | 57 | 63 | 66 | 69 | 73 | 76 | 79 | 88 | 92 | 100 |

| min | 37 | 39 | 45 | 47 | 49 | 52.8 | 55.8 | 61.8 | 64.8 | 67.8 | 71.8 | 74.8 | 77.8 | 86.6 | 90.6 | 98.6 | |

| w | maks | 29 | 31 | 34 | 36 | 38 | 42 | 45 | 48 | 51 | 54 | 58 | 61 | 64 | 68 | 72 | 80 |

| min | 28.48 | 30.28 | 33.38 | 35.38 | 37.38 | 41.38 | 44.38 | 47.38 | 50.26 | 53.26 | 57.26 | 60.26 | 63.26 | 67.26 | 71.26 | 79.26 | |

| m1 | min | 21.9 | 23.5 | 25.9 | 27.5 | 29.1 | 32.3 | 34.7 | 37.1 | 39.3 | 41.7 | 44.9 | 47.3 | 49.7 | 52.9 | 56.1 | 62.5 |

| n | maks | 7.36 | 7.36 | 9.36 | 9.36 | 9.36 | 9.36 | 9.36 | 11.43 | 11.43 | 11.43 | 11.43 | 11.43 | 11.43 | 14.43 | 14.43 | 14.43 |

| min | 7 | 7 | 9 | 9 | 9 | 9 | 9 | 11 | 11 | 11 | 11 | 11 | 11 | 14 | 14 | 14 | |

| s | max=saiz nominal | 55 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | 95 | 100 | 105 | 110 | 115 | 120 | 130 | 145 |

| min | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 | 97.8 | 102.8 | 107.8 | 112.8 | 117.8 | 127.5 | 142.5 | |

| Siri â¡ | Pin Pisah seperti dalam DIN EN ISO 1234 | 6.3x63 | 6.3x71 | 8x71 | 8x80 | 8x80 | 8x90 | 8x100 | 10x100 | 10x100 | 10x112 | 10x112 | 10x125 | 10x140 | 10x140 | 10x140 | 10x160 |

| setiap 1000 unitâkg | 447 | 584 | 710 | 860 | 1060 | 1300 | 1500 | 1800 | 2150 | 2500 | 2900 | 3300 | 3700 | 4100 | 5450 | 7600 | |

â ,Bilangan Slot:

â¤M39: 6

M42~M68: 8

â¥M72: 10

â¡,Panjang pin belah telah diberikan untuk panduan sahaja.

â¢,Bahan:

a) Keluli, Kelas harta: d < 5mm: tertakluk kepada persetujuan; 5mmâ¤dâ¤39mm: 6,8,10; d > 39mm: tertakluk kepada persetujuan. Standard DIN EN ISO 898-2

b) Keluli tahan karat, Kelas harta: dâ¤20mm: A2-70; 5mm < dâ¤39mm: A2-50; d > 39mm: tertakluk kepada persetujuan. Standard DIN EN ISO 3506-2

c) Logam bukan ferus, Kelas sifat (bahan): CuZn=aloi zink kuprum. Standard DIN EN 28839

DIN 935-3 - Kacang Berslot Heksagon 2000 - Bahagian 3: Benang Padang Kasar Metrik, Gred Produk C

| Saiz benang D |

M12 | M16 | M20 | M24 | (M27) | M30 | (M33) | |

| d | ||||||||

| P | Pitch | 1.75 | 2 | 2.5 | 3 | 3 | 3.5 | 3.5 |

| da | min | 12 | 16 | 20 | 24 | 27 | 30 | 33 |

| maks | 13 | 17.3 | 21.6 | 25.9 | 29.2 | 32.4 | 35.6 | |

| dw | min | 16.1 | 21.7 | 27.7 | 33.2 | 38 | 42.7 | 46.6 |

| e | min | 19.85 | 26.17 | 32.95 | 39.55 | 45.2 | 50.85 | 55.37 |

| m | max=saiz nominal | 15 | 19 | 22 | 27 | 30 | 33 | 35 |

| min | 13.2 | 16.9 | 19.9 | 24.9 | 27.9 | 30.5 | 32.5 | |

| M1 | min | 10.6 | 13.5 | 15.9 | 19.9 | 22.3 | 24.4 | 26 |

| n | min | 3.5 | 4.5 | 4.5 | 5.5 | 5.5 | 7 | 7 |

| maks | 3.98 | 4.98 | 4.98 | 5.98 | 5.98 | 7.58 | 7.58 | |

| s | max=saiz nominal | 18 | 24 | 30 | 36 | 41 | 46 | 50 |

| min | 17.57 | 23.16 | 29.16 | 35 | 40 | 45 | 49 | |

| w | min | 9.48 | 12.3 | 15.3 | 18.16 | 21.16 | 23.16 | 25.16 |

| maks | 10 | 13 | 16 | 19 | 22 | 24 | 26 | |

| Siri | Pin splint (ISO 1234) | 3.2 × 22 | 4 × 28 | 4 × 36 | 5 × 40 | 5 × 45 | 6.3 × 50 | 6.3 × 56 |

| setiap 1000 unitâkg | - | 44 | 82 | 142 | 208 | 295 | 352 | |

Bahan:

Keluli, Kelas hartanah: â¤M16: 5ï¼> M16: 4. Standard DIN EN 20898-2